Top 6 Ways Rapid Prototyping Saves Development Time and Costs

Discover top practical ways rapid prototyping helps you cut development time and costs, catch design flaws early, speed approvals, avoid expensive tooling mistakes, etc.

Discover top practical ways rapid prototyping helps you cut development time and costs, catch design flaws early, speed approvals, avoid expensive tooling mistakes, etc.

Build a prototype within the first two weeks of your project, when changes cost hundreds instead of thousands. A $2,000 prototype can prevent a $50,000 tooling error. A three-day test can reveal the assembly flaw that would have added $1.2 million in annual labor costs. A single user feedback session with a working model can expose the design problem that would have triggered a product recall.

The companies saving the most money aren't necessarily spending less on prototyping; they're spending it earlier and more strategically. They're testing real user interactions before committing to production.

This blog shows you exactly where rapid prototyping delivers the biggest time and cost savings, and how to position it in your development process to capture those benefits early.

✓ Early prototyping prevents costly design and tooling errors by revealing issues before production begins.

✓ Physical prototypes speed up approvals by demonstrating real form, fit, and function instantly.

✓ Rapid prototyping shortens development cycles with quick, affordable iteration using 3D printing or CNC.

✓ Iterative testing allows design refinement without heavy tooling costs, reducing long-term development risk.

✓ Prototype-based market validation ensures demand and usability before full-scale manufacturing investment.

Rapid prototyping is a fast, iterative approach to creating physical models or working samples of a product before committing to full-scale manufacturing.

The process typically involves advanced manufacturing technologies like 3D printing, CNC machining, or injection molding to create functional prototypes.

What makes rapid prototyping different from traditional methods is the speed and the flexibility it offers.

This approach also supports the importance of user-centered design by enabling real user testing early in development.

Key elements:

Iteration: You can repeat design → prototype → test cycles rapidly.

Low commitment: You don’t invest heavily in tooling upfront.

Feedback loop: You test with real users or engineers early.

Because of these traits, rapid prototyping accelerates the product development process and reduces risk long before you hit full production.

Image Source - Teamrapidtooling

| Material | Resin-based (ABS equivalent) |

| Process | 3D printing - SLA technology |

| Post finish | Smooth - semi-gloss coating |

| Color | Custom options available |

| Tolerance | ±0.15 mm |

| Lead time | 6 business days |

1. Catches Design Flaws Before Production

Finding a design problem after you've invested in production tooling can cost tens of thousands of dollars to fix. Precise rapid prototype solutions will change this completely.

When you create a physical prototype, problems that looked fine on screen become obvious. Maybe a component is too fragile for real-world use, or two parts don't fit together as smoothly as the CAD model suggested. Perhaps the product is uncomfortable to hold, or a crucial feature is harder to access than intended.

These discoveries during the prototype phase cost a fraction of what they would during production.

2. Eliminates Expensive Tooling Changes

Production tooling represents one of the largest upfront investments in manufacturing.

A single injection mold can cost anywhere from $5,000 to over $100,000, depending on complexity. Once that tool is cut, making changes becomes extremely expensive and time-consuming.

Rapid prototyping lets you refine every detail of your design before committing to production tooling.

You can test multiple iterations, adjust dimensions, modify features, and perfect the design while still working with inexpensive prototype materials and methods.

3. Speeds Up Approval Cycle

Getting buy-in from investors, executives, or clients is easier when you can put a physical product in their hands.

Digital renderings and technical drawings require imagination and technical understanding, but a prototype communicates your vision instantly to anyone, regardless of their technical background.

Approval meetings that might take weeks can be resolved in a single session when there's a prototype available.

Questions get answered immediately. Concerns about size, weight, or functionality can be addressed with direct experience rather than abstract discussion.

4. Reduces Development Cycle Time

Traditional product development follows a linear path: design, build a prototype, test, redesign, build a new prototype, test again.

Each cycle takes weeks or months because prototyping methods were slow and expensive.

Rapid prototyping can change this into a continuous, fast-moving process. You can have a new iteration in days. This speed compresses development timelines dramatically.

5. Enables Cost-Effective Design Iteration

Every product benefits from iteration, testing an idea, learning from it, and improving the next version.

The problem with traditional development is that each iteration is expensive, which limits how many cycles you can afford.

Rapid prototyping makes iteration economically possible.

Creating five or ten prototype versions costs a fraction of what traditional prototyping methods would require. This affordability means you can explore more possibilities and refine details that might otherwise be left "good enough."

6. Validates Market Demand Before Full Investment

Creating an entire production run only to discover limited market interest is not good for the business. Rapid prototyping lets you test market response before committing to full-scale manufacturing.

You can bring prototypes to trade shows, conduct focus groups, or run small programs with actual users. Their feedback tells you whether the product meets real needs and what price point the market will accept. (This is much easier.)

Want to save product development time and costs? Outsource rapid prototyping services to iMAC.

This is the work(rapid prototyping) we've done across industries where precision matters and mistakes cost too much.

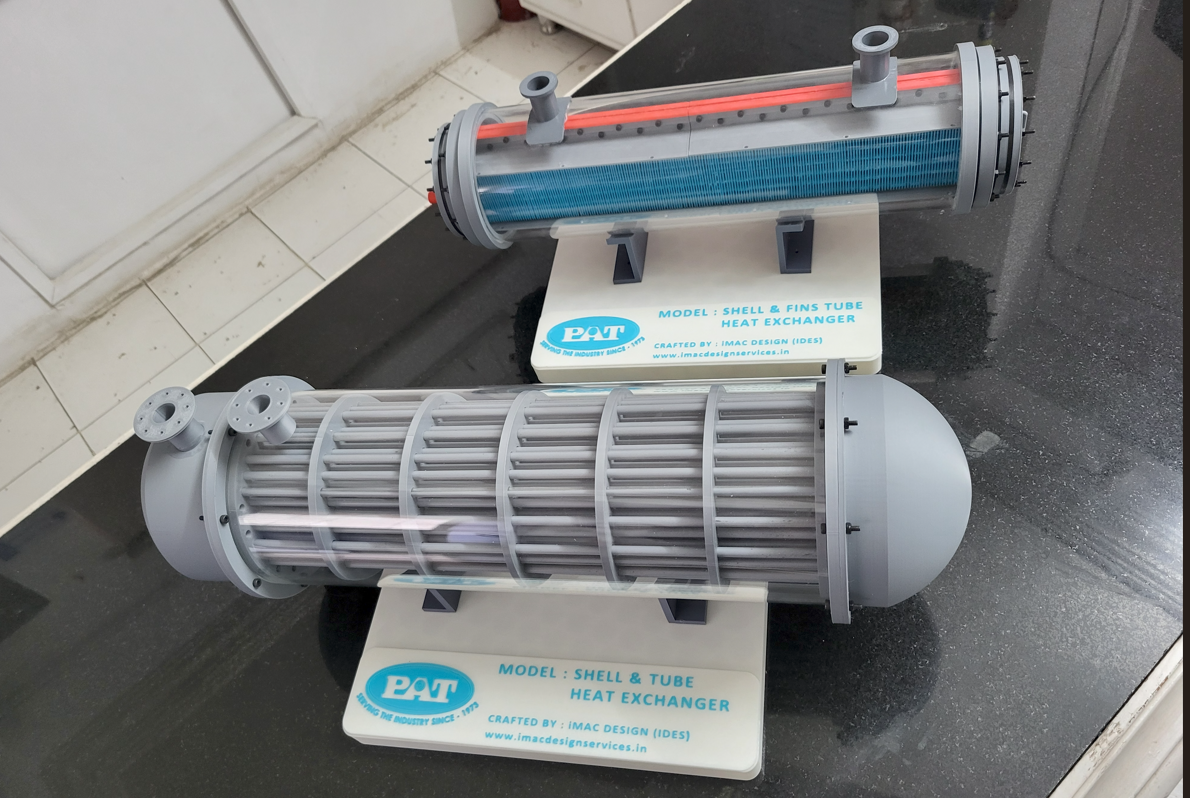

1. Heat Exchanger Miniature Model

Industry: Thermal Engineering / HVAC & Process Equipment

Prototyping Solution: Functional Rapid Prototype using 3D Printing (ABS Resin + Acrylic Assembly)

2. Solar Tracker Miniature Model

![]()

Industry: Renewable Energy / Solar Technology

Prototyping Solution: Scaled Working Prototype with Motion Simulation (Mechatronics + PLA/ABS Printing)

3. Caravan Fan Prototype

Industry: Automotive / Consumer Electronics

Prototyping Solution: Functional Prototype using SLA 3D Printing with Electronic Integration.

4. Aircraft Miniature Model (Airbus A320)

Industry: Aerospace & Aviation

Prototyping Solution: Precision Scaled Model using SLA 3D Printing and Surface Finishing.

Rapid prototyping is most effective when tied into holistic product design and development expertise which bridges prototype to market-ready design.

Every prototype you build early saves you from more expensive fixes later.

The companies winning in competitive markets aren't the ones with the biggest budgets; they're the ones making smarter decisions faster. They test before they invest. They validate before they scale. They learn from real prototypes instead of theoretical designs.

At iMAC Design & Engineering, we have built our expertise around one simple principle: the right prototype at the right time eliminates waste and accelerates success. Partner with us for expert rapid prototyping services.

Rapid prototyping significantly reduces time by quickly creating functional models for testing and feedback. This allows design flaws to be identified and corrected much earlier in the cycle, minimizing the need for costly and time-consuming rework later on.

While highly visible in manufacturing and product design, rapid prototyping is suitable for nearly any industry. It is used across aerospace, medical, automotive, and even software development to accelerate iteration and validation of concepts or components.

By quickly generating and testing multiple design iterations, rapid prototyping accelerates the entire development cycle. It speeds up validation, reduces production errors, and ensures a final, market-ready product is achieved in a much shorter timeframe.