During our ID phase, our designers research multiple design directions through sketching, ideation sessions, and rapid prototyping. We generate diverse concepts that address functional requirements while pushing creative boundaries. Each concept is evaluated against user needs, technical constraints, manufacturing requirements, and brand alignment.

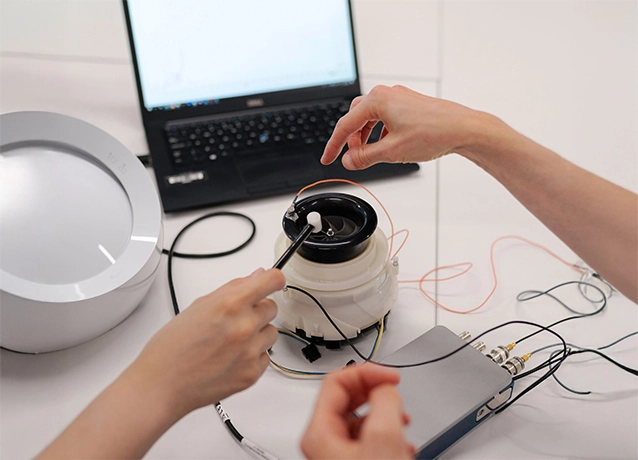

Our team of engineers at iDES builds fully functional prototypes that validate every detail, such as mechanical, electrical, and user-focused. We ensure your product not only looks good but also performs reliably before moving into full-scale production.

Our IoT solutions enable businesses to make data-driven decisions and unlock the full potential of their connected devices and sensors. Our embedded systems integrate hardware and software to power smart features, connectivity, and data flow, converting standalone devices into smart innovations.

Our software development team builds robust, scalable firmware, mobile apps, cloud dashboards, and custom interfaces integrated with your hardware. Using agile methods, continuous testing, and strict QA, we improve functionality, user experience, and long-term reliability for your product ecosystem.

Before launching a product to market, we follow the validation process that includes steps of functional testing, environmental and stress testing, compliance verification, and user trials that ensure performance level and safety, and regulatory standards, reducing risks, revisions, and guaranteeing real-world reliability.

Our tooling design service creates custom molds/jigs for production, while manufacturing will help us convert raw materials into final parts/products. We optimize both processes to deliver durable, cost-effective components following strict quality control parameters.

At iMAC Design and Engineering, we help you simplify the journey from your initial vision to a working prototype that shows exactly how your product will look, feel, and function in the real world.

As a trusted product design studio and product development company, we start with sketches, build working prototypes, and support the entire journey through manufacturing. From medical devices, smart gadgets, wearables, laboratory equipment, and consumer products etc., we create solutions that are built for real use.

Our team brings together creative thinking and solid engineering to tackle tough challenges across multiple sectors. We design with people in mind and refine every detail until the product feels right. With 30+ global clients and 100+ successful projects, we have delivered products that perform and stand out. You will find some of our most recognised product designs in our portfolio for many brands, business types, and industries.

You get end-to-end support - from concept development and CAD modelling to prototyping and DFM, ensuring faster execution, reduced costs, and smooth collaboration through every product development phase.

The designs that we develop are manufacturing-friendly and are approved by vendor specifications, so that your product can get into the phase of production without any delays.

Your intellectual property is safe with us. We operate under strict NDAs, maintain secure data protocols, and ensure full confidentiality from design research through engineering handoff and production tooling.

We bring clarity to complex ideas. Through feasibility studies, design research, and technical exploration, we help refine your product vision into a functional, user-aligned, and manufacturable solution.

Our iterative approach involves rapid prototyping, usability testing, and user validation, ensuring your product aligns with market needs, performs reliably, and delivers real value before final production.

With proven processes and in-house capabilities, we reduce design revisions, compress timelines, and support quicker time-to-market, without compromising quality, compliance, or long-term product performance.

We assess your idea against manufacturing realities, material options, and cost implications.

As concepts progress toward detailed engineering, documentation created through professional mechanical CAD drafting services ensures design intent is accurately translated into manufacturable data.

Physical validation before production investment.

Performance verification under real conditions.

Volume manufacturing with process controls that maintain part quality across the production cycle.

We manage everything from concept development to production launch, covering design, prototyping, engineering, and DFM with one experienced team working with your product’s complete lifecycle.

We prepare engineering outputs like BOMs, CTF drawings, and tolerance stack-ups to ensure manufacturability, cost-efficiency, and minimal design revisions during mass production.

We develop working prototypes to explore design alternatives, verify technical feasibility, and identify potential failures, ensuring confident decision-making before moving into production tooling.

We partner with startups to engineer complex concepts - providing hands-on guidance, technical expertise, and flexible workflows that turn innovative ideas into achievable, launch-ready products.

We start by understanding your vision, then conduct market research and competitor analysis to define precise product requirements and opportunities.

Our designers explore multiple concepts through sketches and brainstorming, then refine the best design for function, aesthetics, and brand alignment.

Our engineers build working prototypes to test functionality, performance, and user experience so that your product works smoothly without any errors.

We develop custom embedded systems that enable wireless communication, process sensor data, and provide control, transforming your product into a connected and intelligent solution.

We deliver secure and scalable software, including firmware, mobile applications, and cloud platforms that have a smooth and reliable integration with your hardware for an excellent user experience.

We conduct thorough testing, including environmental, compliance, and user trials, to guarantee your product is safe and ready for market launch.

We optimize designs for manufacturability, oversee tooling development, and collaborate with trusted partners to produce high-quality parts with consistent accuracy.

We assist with packaging, certifications, and market introduction, followed by ongoing engineering support for future iterations or scaling needs.

We offer end-to-end product development services, guiding your concept from initial ideation through to manufacturing support. While we are equipped to manage the entire lifecycle, we can also engage at specific stages based on your needs, such as concept generation, prototyping, engineering design, or design for manufacturing. Our flexible approach ensures you receive support precisely where it's required.

We specialize in product design across a diverse range of industries, including oil & gas, heavy industry, medical devices, security & surveillance, laboratory equipment, smart devices/IoTs, consumer industry, FMCG, agriTech, dairy tech, and clean tech.

Yes, we can assist with manufacturing once the product design is finalized. Our services extend to Design for Manufacturability (DFM) optimization, identifying suitable manufacturing partners, supplier vetting, and overseeing the initial production runs. While we typically don't directly own manufacturing facilities, we utilize our network and expertise to facilitate a smooth transition from design to scalable production.

For detailed information on the cost structure for our product design and development services, please contact us. Our pricing is customized based on the project's scope, complexity, required expertise, and anticipated duration. We offer transparent proposals after understanding your specific needs.

Yes, we work with existing products to improve, refine, or completely redesign them. Whether you're looking to enhance functionality, improve user experience, reduce manufacturing costs, update aesthetics, or adapt to new technologies, our team can analyze your current product, identify areas for optimization, and implement innovative solutions to achieve your goals.

Yes, you will own the final product design and all associated intellectual property. Our standard agreements ensure that all deliverables and IP generated during the project are assigned to you. To protect your design, we recommend:

Non-Disclosure Agreements (NDAs): Signed for all parties involved in the development process.

Patent Filings: Pursuing utility or design patents based on innovation.

Copyrights: For specific design elements.

Trademark Registration: For branding and product names.

We can guide you on best practices for IP protection relevant to your specific product.