Sustainable Product Design: What It Is & Why It Is Important

Understand what sustainable product design is, why it matters, and how companies can create eco-conscious, innovative products for a greener future.

Understand what sustainable product design is, why it matters, and how companies can create eco-conscious, innovative products for a greener future.

Sustainable product design is changing the way we think about products and their impact on the planet. Instead of focusing only on function or cost, this approach considers the entire lifecycle from material selection and production to usage and end-of-life.

The goal is to minimize waste, lower emissions, and create items that last longer and perform better.

For businesses, it’s an opportunity to innovate, meet the demands of eco-conscious consumers, and shape a future where design and sustainability work hand in hand!

✓ Sustainable design integrates environmental and social responsibility throughout a product’s entire lifecycle.

✓ It offers businesses a competitive advantage, reducing long-term costs and meeting rising consumer and regulatory demands for eco-friendly products.

✓ The process moves beyond “do not harm” to active innovation, creating products that can be repaired, recycled, and even contribute to a regenerative economy.

✓ Despite initial costs and material challenges, sustainable design drives brand value and future-proofs companies by encouraging customer loyalty and technological innovation.

Sustainable product design is the practice of creating products that meet user needs while reducing negative impacts on the environment and society.

It focuses on the full product lifecycle from choosing eco-friendly materials to ensuring energy-efficient manufacturing, long-lasting performance, and responsible end-of-life disposal.

The aim is to balance function, performance, and cost with sustainability.

At its core, sustainable product design means creating products that:

Use fewer natural resources

Generate less waste and pollution

Last longer and perform better

Can be easily repaired, upgraded, or recycled

Consider the social and environmental impact at every stage

EXAMPLE -

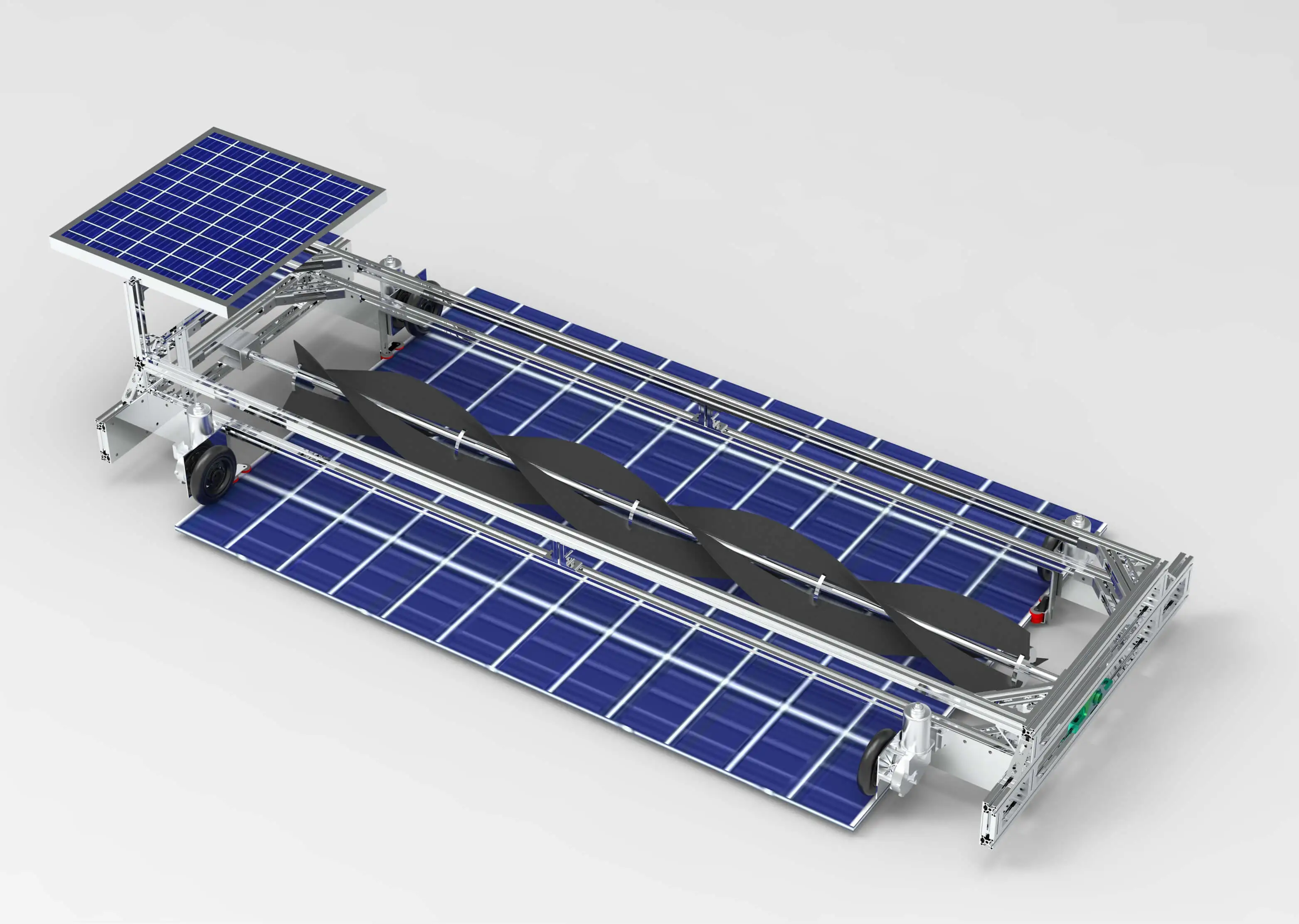

The Solar Cleaning Robot is an automated solution designed to keep solar panels clean and operating at peak efficiency. By using a self-powered, water-efficient cleaning mechanism, it reduces both energy losses and maintenance costs.

Product Highlights:

Self-powered system with integrated solar panels.

Eco-friendly dry cleaning minimizes water use.

Automated cleaning for consistent efficiency.

Lightweight & modular for scalability and easy deployment.

This product demonstrates how sustainable engineering design can improve renewable energy infrastructure while conserving resources.

The importance lies in three key areas:

Environmental responsibility – Traditional design often relies on resource-intensive materials and processes that contribute to pollution, carbon emissions, and waste.

By prioritizing sustainable choices, companies can lower their ecological footprint and align with global climate goals.

Economic advantage – Designing products sustainably helps businesses cut long-term costs through material efficiency, energy savings, and reduced waste management expenses.

More importantly, it drives innovation, pushing brands to rethink packaging, sourcing, and supply chains in ways that open new market opportunities.

Consumer trust and compliance – Today’s consumers actively seek brands that demonstrate responsibility.

At the same time, governments are enforcing stricter sustainability regulations. Companies that embed sustainable design are better positioned to earn loyalty, meet compliance requirements, and build long-term resilience.

For example, industries worldwide are now exploring circular economy principles, designing products for reuse, recycling, or remanufacturing to minimise waste. This isn’t just a trend but a fundamental shift in how businesses compete.

That’s why more organisations are turning to product design and development solutions that integrate sustainability into the very first step of designing products, ensuring they remain relevant & competitive in an evolving market!

Companies are moving towards environmentally friendly product design because it is a smarter, safer, and efficient way to do business.

Sustainable choices lower long-term costs, meet rising consumer expectations, and keep brands compliant with increasingly strict eco-design regulations.

In other words, it’s not just about protecting the planet; it’s about protecting profitability and relevance.

From our own experience working with a mid-sized manufacturer, we have witnessed how a simple switch to recycled polymers during a product redesign cut waste disposal fees and improved customer feedback.

Industry data supports this shift. A 2024 Gartner report found that 75% of CEOs expect sustainability to drive product innovation in their companies within five years, a powerful signal that environmental responsibility is becoming a foundation of strategy.

Experts echo this urgency. As Dr. Leila Norton, Senior Sustainability Scientist at MIT’s Center for Industrial Ecology, explains:

“Design decisions made at the concept stage determine up to 80–90% of a product’s lifetime environmental impact. Changing practices later is exponentially harder.”

This expert insight shows why companies are embedding sustainability directly into the early design phase because fixing problems downstream costs more, both financially and environmentally.

Of course, some remain unconvinced, questioning whether sustainable design drives up costs. But when businesses factor in material savings, regulatory compliance, consumer loyalty, and long-term brand resilience, the data shows the opposite.

With the right outsourcing product design partner, companies can model these trade-offs transparently, building trust that sustainability is not only achievable but also profitable.

Life Cycle Thinking

Life cycle thinking forms the foundation of sustainable product development, requiring teams to consider environmental and social impacts across every stage of a product's journey from raw material extraction through manufacturing, distribution, use, and end-of-life management.

This principle demands that development teams conduct comprehensive Life Cycle Assessments (LCA) to identify impact areas and optimization opportunities.

Rather than focusing solely on manufacturing efficiency, teams evaluate carbon footprint, water usage, waste generation, and social implications across the entire value chain.

Circular Design Philosophy

Circular design principles focus on creating products that maintain material value throughout multiple use cycles, effectively designing out waste and pollution while keeping products and materials in continuous use.

Core Strategies:

✓ Design for Disassembly: Products are engineered so components can be easily separated for repair, reuse, or recycling

✓ Material Selection: Prioritizing renewable, recycled, and biodegradable materials that support circular material flows

✓ Modularity: Creating products with interchangeable components that extend product life and reduce replacement needs

Dematerialization

Dematerialization focuses on delivering the same or improved functionality while using fewer materials, less energy, and reduced physical resources throughout the product development process.

Strategic Approaches:

✓ Lightweighting: Reducing material usage through advanced engineering and design optimization

✓ Digitalization: Replacing physical components with digital solutions where possible

✓ Service Integration: Shifting from product ownership to service models that maximize utilization efficiency

Social Equity and Stakeholder Inclusion

Sustainable product development extends beyond environmental considerations to encompass social justice, fair labor practices, and inclusive design that serves diverse user populations.

Key Components:

✓ Inclusive Design: Ensuring products are accessible to users with varying abilities, economic circumstances, and cultural backgrounds

✓ Supply Chain Ethics: Implementing fair wage practices, safe working conditions, and community investment throughout the value chain

✓ Stakeholder Engagement: Involving communities, workers, and end-users in the development process to ensure solutions address real needs

✓ Business Value: Companies prioritizing social equity in product development report higher employee satisfaction, stronger brand loyalty, and improved market access in diverse global markets

Systems Thinking and Interconnectedness

This principle recognizes that products exist within complex interconnected systems and that sustainable development requires understanding and optimizing these broader systemic relationships.

Application Areas:

✓ Infrastructure Compatibility: Designing products that integrate seamlessly with existing sustainable infrastructure

✓ Ecosystem Impact: Considering how products affect broader ecological and social systems

✓ Value Network Optimization: Collaborating with suppliers, distributors, and partners to optimize sustainability across the entire value network

Innovation Through Constraints

Sustainable product development treats environmental and social constraints not as limitations but as innovation triggers that drive breakthrough solutions and competitive differentiation.

Innovation Outcomes:

✓ Material Innovations: Developing new sustainable materials that outperform traditional alternatives

✓ Process Improvements: Creating manufacturing processes that reduce waste while improving quality

Regenerative Impact

The most advanced sustainable product development goes beyond "doing less harm" to actively improving environmental and social conditions through product design and deployment.

Regenerative Strategies:

✓ Carbon Negative Products: Designing products that sequester more carbon than they emit throughout their lifecycle

✓ Ecosystem Restoration: Creating products that contribute to environmental restoration efforts

✓ Community Development: Developing products that strengthen local economies and social structures

The green product development process encompasses a methodology that evaluates every design decision through the lens of sustainability.

This means considering material sourcing, manufacturing processes, energy consumption, packaging, distribution, user experience, and disposal or recycling possibilities before finalizing any design element.

Environmentally conscious design requires teams to think beyond immediate product requirements and consider long-term implications for both users and the planet.

Phase 1: Research and Impact Planning

Circular design principles begin with comprehensive research examining existing solutions and environmental opportunities.

Teams conduct life cycle assessment integration to quantify potential impacts across all product stages, establishing sustainability goals that align with business objectives.

Phase 2: Sustainable Material Selection

Material choices represent the most essential sustainability decisions. Sustainable material selection involves evaluating renewable options, recycled content, biodegradable alternatives, and low-impact manufacturing processes.

Advanced teams implement material passports that track environmental credentials throughout the supply chain.

Phase 3: Design for Circularity

Circular design principles require products designed for disassembly, repair, and component reuse.

Teams implement design approaches and nature-inspired product design, studying natural systems for resource-efficient solutions that eliminate waste.

Phase 4: Sustainable Prototyping Methods

Testing extends beyond functionality to include environmental performance validation. Sustainable prototyping methods evaluate user behaviors, lifecycle performance, and circularity effectiveness before final production commitment.

Also to add, by avoiding common product design mistakes and embedding eco-conscious product development practices, brands can future-proof their portfolios and meet the rising demand for greener, smarter solutions.

Challenge 1 - Material Limitations

One of the biggest challenges lies in sourcing eco-friendly product development materials.

Many sustainable alternatives, such as biodegradable plastics or recycled composites, still lack the durability or scalability of conventional materials.

Challenge 2 - High Initial Costs

Shifting to green product engineering requires upfront investment in new technologies, specialised machinery, and supply chain changes.

While long-term savings are possible, the initial cost often discourages smaller companies from adopting these practices.

Challenge 3 - Complex Supply Chains

Ensuring sustainability across the entire supply chain is difficult. Even if the final product uses eco-conscious materials, transportation, packaging, and vendor practices may not align with environmentally conscious design principles.

Sustainable design is a pillar of good engineering; learn how our product design and development services embed eco-friendly practices throughout the lifecycle.

This makes full lifecycle sustainability harder to achieve.

Challenge 4 - Performance vs. Sustainability Trade-offs

Consumers expect sustainable products to perform as well as or better than traditional ones.

However, compromises may arise, such as reduced shelf life, higher fragility, or limited usability. Balancing circular product design with customer satisfaction is often a difficult task.

Challenge 5 - Regulatory and Compliance Pressures

Governments worldwide are tightening regulations on waste, emissions, and product safety. While this drives sustainability, it also adds complexity.

Companies must stay updated on evolving standards and ensure that sustainable innovation in product design meets both local and global requirements.

Challenge 6 - Consumer Awareness and Acceptance

Ironically, another barrier is consumer behaviour. Many buyers support sustainability in theory, but hesitate to pay a premium for greener products.

Bridging this gap requires educating consumers and communicating the value of eco-conscious product development in a way that connects with them.

Challenge 7 - Technological Gaps

Not all industries have access to advanced technologies like biomimetic design or AI-driven material optimisation.

Smaller manufacturers often struggle to adopt innovations that larger corporations can easily integrate.

“The greatest barrier to sustainable design is the ability to scale those ideas without losing affordability or functionality”.

Embracing custom sustainable product development goes beyond environmental responsibility; it creates measurable value for businesses, consumers, and society.

Unlike generic approaches, customisation allows companies to align eco-friendly product development with specific brand goals, market needs, and industry standards.

1. Competitive Advantage and Brand Reputation

Consumers increasingly prefer brands that practise environmentally conscious design. Offering tailor-made sustainable products signals authenticity, builds trust, and positions a company as a leader in innovation.

A Nielsen report shows that 73% of global consumers are willing to pay more for products from sustainable brands.

2. Cost Efficiency in the Long Term

Although the initial investment in green product engineering can be high, custom solutions often lead to reduced material waste, optimised energy use, and lower disposal costs.

By designing with sustainability in mind from the start, businesses save resources and avoid costly redesigns later.

3. Regulatory Compliance and Risk Reduction

With evolving global sustainability regulations, businesses that embed eco-conscious product development minimise risks of fines, recalls, or reputation damage.

Custom solutions ensure compliance not just locally but across international markets.

4. Consumer Loyalty and Differentiation

Tailoring sustainability features to consumer needs, such as modularity, recyclability, or longer product lifespans, creates stronger brand loyalty.

Customers perceive such products as thoughtful and future-ready, enhancing overall customer experience.

5. Supports Circular Economy Models

Circular product design strategies, such as designing for reuse or easy recycling, keep materials in use longer and reduce dependency on virgin resources.

Customised sustainable development ensures that each product contributes meaningfully to a circular economy.

6. Innovation and Future-Proofing

Investing in sustainable innovation in product design drives companies to explore new technologies like biomimetic design, AI-assisted material selection, or renewable energy integration.

These innovations not only address today’s challenges but also prepare businesses for future demands.

As innovation consultant David Lee notes, “Custom sustainability is not just about building greener products, it’s about designing systems that adapt to change, scale with demand, and inspire long-term value."

Sustainable product design, also known as "eco-design" or "green design," is the practice of creating products with the goal of minimizing their negative environmental and social impact throughout their entire life cycle.

Sustainable product design is important today because it reduces environmental impact, lowers long-term costs, and meets rising consumer and regulatory demands.

The simple answer is that sustainable product design can have a higher initial cost, but it is often more cost-effective in the long term.

The world is moving fast, and sustainability is no longer optional. At iMAC Design and Engineering Services, we make it easier for you to design products that are smarter, greener, and ready for tomorrow’s market.

Partner with us today and lead the way in sustainable innovation in product design.