Plastic Injection Molding: Process, Materials, Advantages, and Applications

Learn how plastic injection molding works, key materials used, major advantages, and real-world applications across industries. A complete guide for manufacturers.

Learn how plastic injection molding works, key materials used, major advantages, and real-world applications across industries. A complete guide for manufacturers.

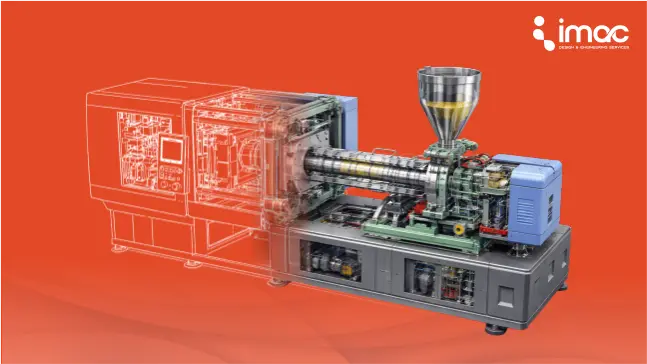

Plastic injection molding is a manufacturing process used to produce consistent, high-volume plastic components across multiple industries. Its effectiveness depends on how early engineering decisions, such as part geometry, material selection, and tooling strategy, are aligned with production requirements.

This blog explains the plastic injection molding process, outlines commonly used materials, highlights real operational advantages, and examines where the process is most effectively applied in industrial product development.

Plastic injection molding melts plastic pellets, forces the molten material into a precision mold cavity under high pressure, cools the part, and ejects a finished component. The process repeats hundreds of times per hour from the same mold, creating identical parts every cycle.

Injection molding favors preparation and discipline. Late design changes and unclear requirements increase cost and complexity.Many manufacturers rely on professional plastic injection molding services to ensure tooling accuracy, stable production cycles, and consistent part quality.

Phase 1: Material Loading and Preparation

Plastic pellets are loaded into a hopper.

For materials sensitive to moisture, like nylon, pre-drying removes water that could damage part quality. Temperature and pressure settings are programmed based on the plastic's melt properties.

Phase 2: Heating and Injection

A rotating screw heats plastic to the melting temperature, then injects molten material into the mold cavity at controlled pressure. High injection pressure forces plastic into every corner of the mold, eliminating voids and sink marks. This phase takes 2-10 seconds, depending on part size.

Phase 3: Cooling

The mold's internal water channels cool the part to a solid state. Cooling time is critical it's where your cycle time is determined. Simple parts cool in 5 seconds; complex parts may need 30 seconds or more.

Phase 4: Ejection

The mold opens, ejector pins push the finished part out, and the mold closes immediately. A new cycle begins. Your 30-second cycle time means 120 parts per hour from one mold.

Phase 5: Secondary Processing

Gates (where plastic enters the mold) re removed. Flash (excess plastic at mold lines) is trimmed. Parts may be printed, assembled, or inspected. Plan secondary operations into your cost structure.

Phase 6 : Quality Verification

Dimensional inspection and visual checks confirm that parts meet defined specifications. This step ensures that production output remains consistent across batches and over time.

ABS (Acrylonitrile Butadiene Styrene)

Strong, impact-resistant, excellent color options. Used in automotive interior trim, tool housings, and electronic enclosures. Machines easily and handles normal operating temperatures well. Not ideal for high-heat applications.

PP (Polypropylene)

Lightweight, chemical-resistant, flexible. Works great for snap fits, hinges, and parts that bend repeatedly. Medical and automotive suppliers depend on PP for cost-effective solutions. One of the most affordable injection molding materials.

Poly Carbonate (PC)

Transparent and strong with excellent temperature resistance. Used for protective eyewear, automotive lighting, and clear protective covers. More expensive than ABS and requires precise temperature control during molding.

PA (Polyamide or Nylon)

Excellent for mechanical components like gears, bushings, and bearing surfaces. Handles repeated motion and friction without degrading. Absorbs moisture, so design must account for dimensional changes in humid environments.

HDPE (High-Density Polyethylene)

Chemical-resistant and lightweight. Common in containers, fluid reservoirs, and industrial parts. Affordable and easy to mold. Less rigid than ABS or PC.

PBT (Polybutylene Terephthalate)

Strong, heat-resistant, excellent dimensional stability. Used in electrical connectors, automotive under-hood components, and industrial equipment housings. Better heat performance than ABS.

PMMA (Polymethyl Methacrylate or Acrylic)

Transparent like glass but lighter and more impact-resistant. Used for optical components, protective shields, and transparent housings. More brittle than polycarbonate but excellent clarity.

PPS (Polyphenylene Sulfide)

High-performance engineering plastic. Resists heat and chemicals exceptionally well. Used in aerospace, automotive under-hood applications, and electrical components. More expensive and requires specialized molding.

Dimensional Consistency Across Production Runs

Injection molding delivers repeatable geometry when tooling and process parameters are properly established. This consistency supports reliable assembly and predictable performance in multi-part systems.

Predictable Cost Structure at Scale

While tooling requires upfront investment, injection molding stabilizes per-part cost once production begins. Controlled cycle times, material usage, and reduced labor dependency support long-term cost planning.

Feature Integration Within a Single Component

Injection molding allows multiple functional features to be incorporated into one part, including:

✓ Mounting points

✓ Clips and snap-fits

✓ Textures and surface details

This reduces the need for secondary operations and simplifies assembly.

Material Properties Aligned With Application Needs

A wide range of thermoplastics can be selected to match functional requirements. This enables performance targets to be met without unnecessary material complexity.

Scalable Production Without Process Redesign

Once tooling and parameters are validated, production volumes can be increased without reconfiguring the core process. This supports demand growth and long-term manufacturing continuity.

Consumer Electronics

Phone cases, laptop bezels, monitor housings, charging ports. These products need 50 million+ units annually only injection molding works at this scale.

Automotive Manufacturing

Dashboard panels, door handles, engine covers, fluid reservoirs, climate control components. Modern vehicles contain hundreds of injection-molded parts.

Medical Device Manufacturing

Syringes, connectors, housing components, and diagnostic equipment covers. Injection molding meets sterility requirements and regulatory standards.

Electrical and Industrial Components

Connectors, enclosures, and equipment housings. Industries rely on injection molding for consistent, reliable component manufacturing.

iMAC Engineering Services supports injection molding projects by aligning part design, material selection, and tooling considerations early in the development process.

Yes. Part geometry is reviewed and refined to support consistent molding performance and dimensional stability.

Material recommendations are based on functional requirements, operating conditions, and long-term performance expectations.

Yes. Designs and tooling strategies are developed to support stable production as volumes increase.

Early involvement is recommended, ideally before tooling decisions are finalized, to reduce rework and improve production outcomes.

Plastic injection molding is the manufacturing standard for high-volume plastic parts because it addresses the need for producing consistent components at a controlled cost per unit.

At iMAC Engineering Services, injection molding projects are approached with a clear focus on production volume, material selection, and mold design three factors that directly influence long-term cost, quality, and production stability. So let’s talk today.