1. Improved Interpretation Across Engineering and Vendors

A well-drafted drawing reduces interpretation gaps between teams.

Engineers, vendors, and production personnel do not read drawings the same way. Drafting that follows clear standards ensures:

✓ Dimensions are interpreted consistently

✓ Critical features are identified correctly

✓ Assumptions are minimized during quoting and execution

This directly reduces clarification cycles and prevents discrepancies between intent and output.

2. Controlled Tolerances That Align With Production Capability

Tolerances are one of the most misunderstood elements in engineering documentation.

Practical CAD drafting:

✓ Applies tight tolerances only where function requires them

✓ Keeps non-critical dimensions flexible

✓ Aligns tolerance strategy with actual manufacturing capability

This balance avoids unnecessary machining complexity while preserving part performance.

3. More Reliable Vendor Quotation and Lead Time Planning

Vendors rely on drawings to estimate:

✓ Machining time

✓ Tooling approach

✓ Material usage

✓ Inspection effort

✓ Incomplete or unclear drawings lead to padded quotes and longer lead times.

Accurate CAD drafting supports realistic pricing and predictable scheduling.

4. Reduced Risk During Production and Assembly

Many production issues do not stem from workmanship, but from unclear documentation.

Effective drafting:

✓ Defines reference datums clearly

✓ Supports proper fit and alignment during assembly

✓ Reduces rework caused by dimensional ambiguity

This becomes increasingly important as assemblies grow in complexity.

5. Consistency Across Revisions and Product Variants

Engineering projects evolve. Drawings must evolve with them.

Structured CAD drafting ensures:

✓ Changes are traceable

✓ Previous revisions are not mistakenly reused

✓ Assemblies remain aligned with updated part drawings

✓ This consistency protects both quality and timelines.

6. Long-Term Documentation Value

Drafting is not just for current production.

Accurate drawings support:

✓ Future redesigns

✓ Supplier changes

✓ Spare part manufacturing

✓ Compliance and audit requirements

This long-term usability is often overlooked, but highly valuable.

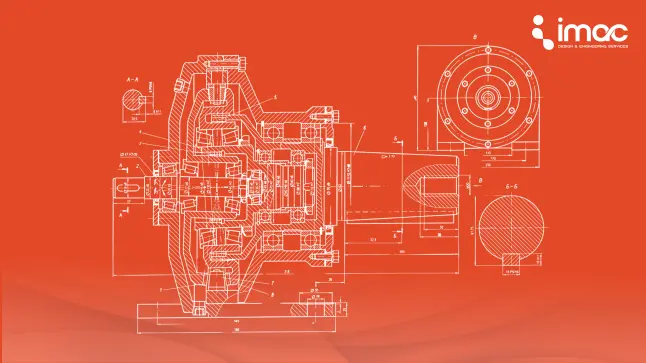

Why This Matters in Practice?

In industrial environments, drafting quality influences cost, clarity, and execution stability. We approach CAD drafting with this lifecycle view treating it as a technical control system rather than just a drafting task. This lifecycle approach aligns closely with early-stage product design and development, where manufacturability and documentation quality are established from the start.