8 Key Stages of the Product Design and Development Process

Discover the 8 key stages of product design and development — from idea to market launch — to build innovative, user-focused, and successful products.

Discover the 8 key stages of product design and development — from idea to market launch — to build innovative, user-focused, and successful products.

Apple's development of the original iPhone perfectly presents the necessary importance of a product design and development process. When Steve Jobs envisioned a device that would combine a phone, iPod, and internet communicator into one revolutionary product, Apple didn't simply jump into production. Instead, they progressed through each stage of development from market research, revealing consumer frustration with existing smartphones. This highlights the importance of product design and development.

Today, there are many promising concepts just like Apple that never reach the market because creators lack a structured approach to convert their vision into reality.

This gap highlights the necessary importance of a professional product design and development process. Successful brands and startups collaborate with experienced teams who systematically convert concepts into excellent products.

These 8 key stages represent the proven framework that holds the power to change your initial ideas into successful products that customers genuinely value and purchase.

✓ Save money and time - Planning helps you find and fix problems early before they become expensive to solve.

✓ Track progress - Clear structure shows completion status and remaining work priorities.

✓ Keep teams focused - Defined steps and goals direct everyone's efforts during development.

✓ Reduce risks - Proven processes help avoid common project challenges.

✓ Make better products - Structured feedback collection improves design and development outcomes.

1. Research & Discovery

Every successful product begins with thorough research and ideation. This phase is foundational in the product design and development lifecycle.

Activities include:

✓ User research

✓ Competitive analysis

✓ Feasibility checks

✓ Initial sketches and mood boards

Our Creations - As a design and development firm, our primary task is to thoroughly understand the client's vision, user needs, market trends, and existing solutions.

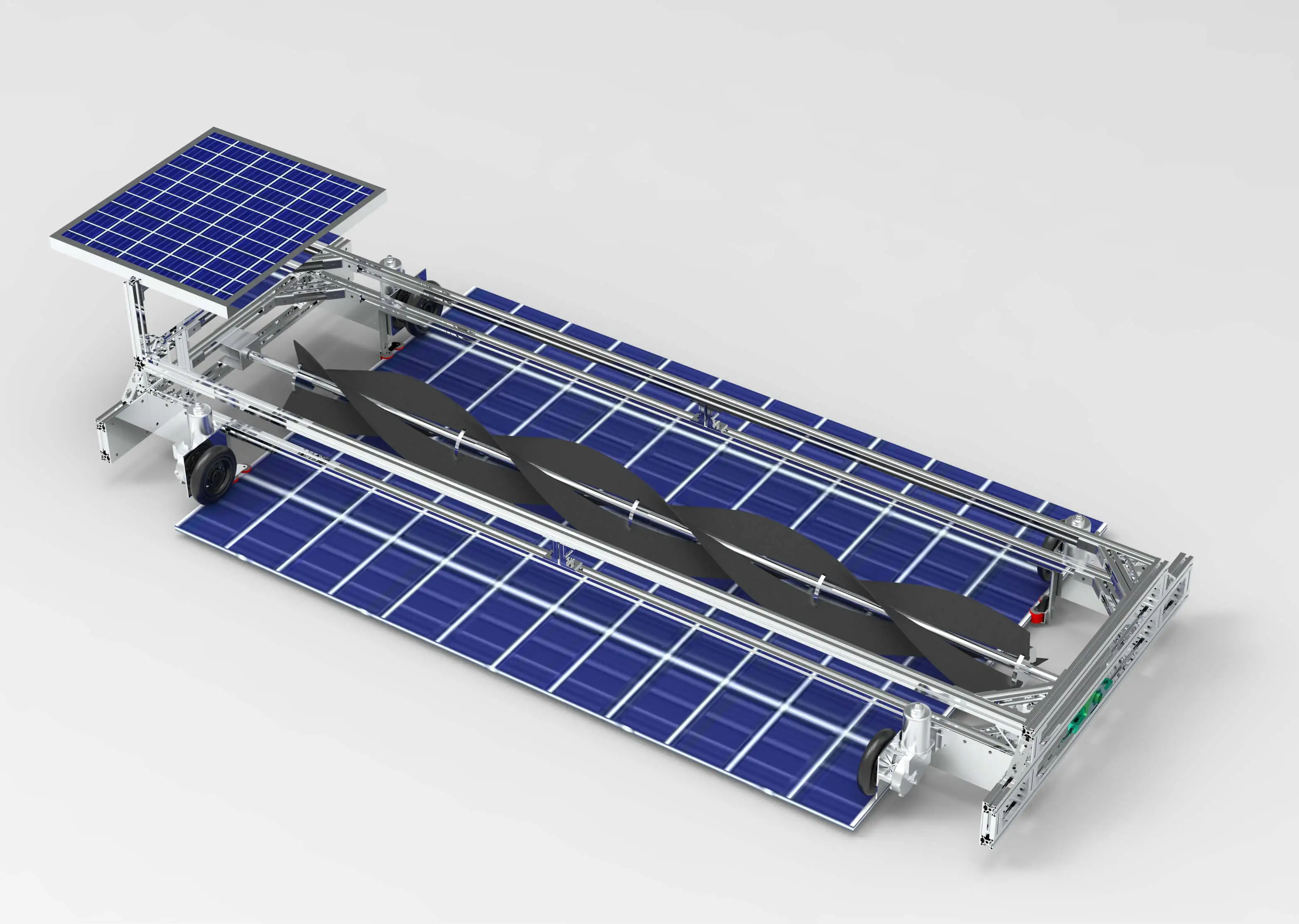

Before designing our automatic solar panel cleaning robot, we studied dust accumulation patterns, climate data, and solar panel layouts across regions.

2. Concept Development & Ideation

In this second stage of the product development process, when market opportunities and user problems are identified, this stage focuses on generating and refining potential solutions. Design teams explore multiple creative approaches through structured brainstorming sessions, competitive analysis, and technical feasibility studies.

Key actions:

✓ Sketching

✓ Wireframing

✓ Initial 3D CAD modelling

✓ Rough functional flow

Our Best Designs : For hospital beds, we explored multiple ergonomic concepts focusing on ease of use and patient comfort.

At specific design stages — such as detailed modeling — companies often rely on mechanical CAD drafting outsourcing solutions to maintain speed and quality.

3. Product Engineering

This stage involves creating technical documentation, establishing performance parameters, and defining the product's core functionality.

Tasks include:

✓ Defining product structure

✓ Selecting materials and components

✓ Mechanical and electrical system design

✓ Simulation (thermal, stress, etc.)

iMAC’s Engineering’s Excellent Design: In our electric vehicle project, we integrated battery packs, frame design, and drive-train configuration with structural and safety considerations.

4. Industrial Design & Ergonomics

The focus shifts to user experience and aesthetic appeal as designers craft the product's physical form and interface. This stage considers human factors, accessibility requirements, and visual design principles.

Includes:

✓ Surface modelling

✓ CMF (Colour, Material, Finish)

✓ UI/UX design

✓ User testing

Best Design and Development Work: In the sheet metal kiosk, we designed an intuitive user interface with high durability for outdoor conditions.

5. Prototyping & Mock-ups (Alpha Stage)

Initial prototypes allow the concepts to be converted into physical products for the first time. These early versions, often rough and functional rather than polished, allow teams to test basic functionality and identify major design flaws.

✓ 3D-printed models

✓ Mock-ups

✓ Basic electronics integration

✓ Form and function testing

Our Innovations : For the solar panel robot, our alpha prototype helped validate climbing ability and dry-cleaning performance.

6. Beta Prototype & User Testing

More refined prototypes undergo strict testing with actual users in real-world systems. This stage validates assumptions about user behavior, identifies usability issues, and gathers feedback on performance.

Beta prototypes closely resemble the final product in form and function, allowing for comprehensive evaluation.

✓ Beta testing with users

✓ Usability feedback

✓ Stress and durability checks

✓ Compliance evaluations

Say for Example: Beta testing of our hospital bed led to improved control interfaces and improved patient safety features.

7. Design for Manufacturing (DFM) & Production Support

This stage involves selecting production methods, specifying tolerances, and creating detailed manufacturing documentation.

Key steps:

✓ Tooling design

✓ Optimising parts for production

✓ BOM finalisation

✓ Vendor and supplier coordination

For the sheet metal kiosk, we optimised the design for laser cutting and modular assembly, reducing production time and cost.

8. Manufacturing, Validation & Launch Support

Production begins with pilot runs to validate manufacturing processes and ensure the effectiveness of quality control systems. Teams monitor initial production batches, addressing any quality issues and refining manufacturing procedures.

✓ Pilot manufacturing

✓ Quality assurance

✓ Assembly and packaging validation

✓ Launch coordination

Say for Example - Our electric vehicle went through battery validation, chassis alignment checks, and full assembly reviews before entering limited production.

At iMAC Engineering, we don’t just explain the product design stages — our full product design and development solutions bring these steps to life for real projects.

We deliver complete, end-to-end product design and development solutions. Over the years, we have developed a set of best practices that help us bring high-quality, functional, and manufacturable products to life on time and within budget.

Here’s how we approach every project:

1. Instead of jumping straight into features or aesthetics, we work with clients to uncover the core pain points, whether it's hospital staff struggling with outdated bed controls or solar panels losing efficiency due to dust. This ensures every design decision is grounded in purpose.

2. We believe in rapid iteration, getting basic versions in hand early, breaking them, fixing them, and learning from each cycle. It’s how we catch flaws early and save both time and cost.

3. We don’t wait until the end to prototype. Whether it’s a simple mock-up or a working alpha build, we prototype early to fail fast, learn quickly, and improve with the process. It saves time and cost later.

4. From part tolerances to material selection and assembly methods is reviewed with manufacturers in mind. Our solutions are practical and cost-efficient.

5. We collaborate closely with clients at every stage. Weekly check-ins, design reviews, and transparent documentation.

6. We don’t assume things will work, we test them. Through functional prototypes, user feedback sessions, and simulation tools, we validate decisions before locking anything down.

7. Our team helps with tooling handover, vendor coordination, and ongoing refinements because true product design and development solutions don’t stop at the prototype stage.

At iMAC Engineering, we build the foundation for long-term success. If you're looking for a partner who delivers practical, tested, and end-to-end product design and development services, you're in the right place.

The main stages of product design and development are ideation, research, design, prototyping, testing, manufacturing, and launch support, guiding a product from concept to market.

The product development lifecycle is important as it provides a structured framework, minimizing risks, controlling costs, and ensuring products satisfy market needs and quality.

Prototyping in product development is essential for creating tangible models for early testing, identifying errors, refining designs, and gathering feedback before final production.

From startup founders bringing their first big idea to life, to established companies expanding their product range, success depends heavily on how to choose the best product design and development company to bring that vision to market.

We specialize in designing innovative concepts into great products that customers actually want to buy.

The eight stages we have outlined are the proven roadmap we use with every client to minimize risk, optimize resources, and accelerate time-to-market.

Ready to move beyond the planning phase? Your product won't design and develop itself.

Start your product journey today →

Get a free consultation on your product concept and learn how we can bring your vision to market faster than you thought possible.